ICANSTEAM

Steam high temperature sterilizer for hospital application

The steam sterilizers iCanSteam are designed for a simple and effective experience for the operators, thanks to the touch screen user friendly interface.

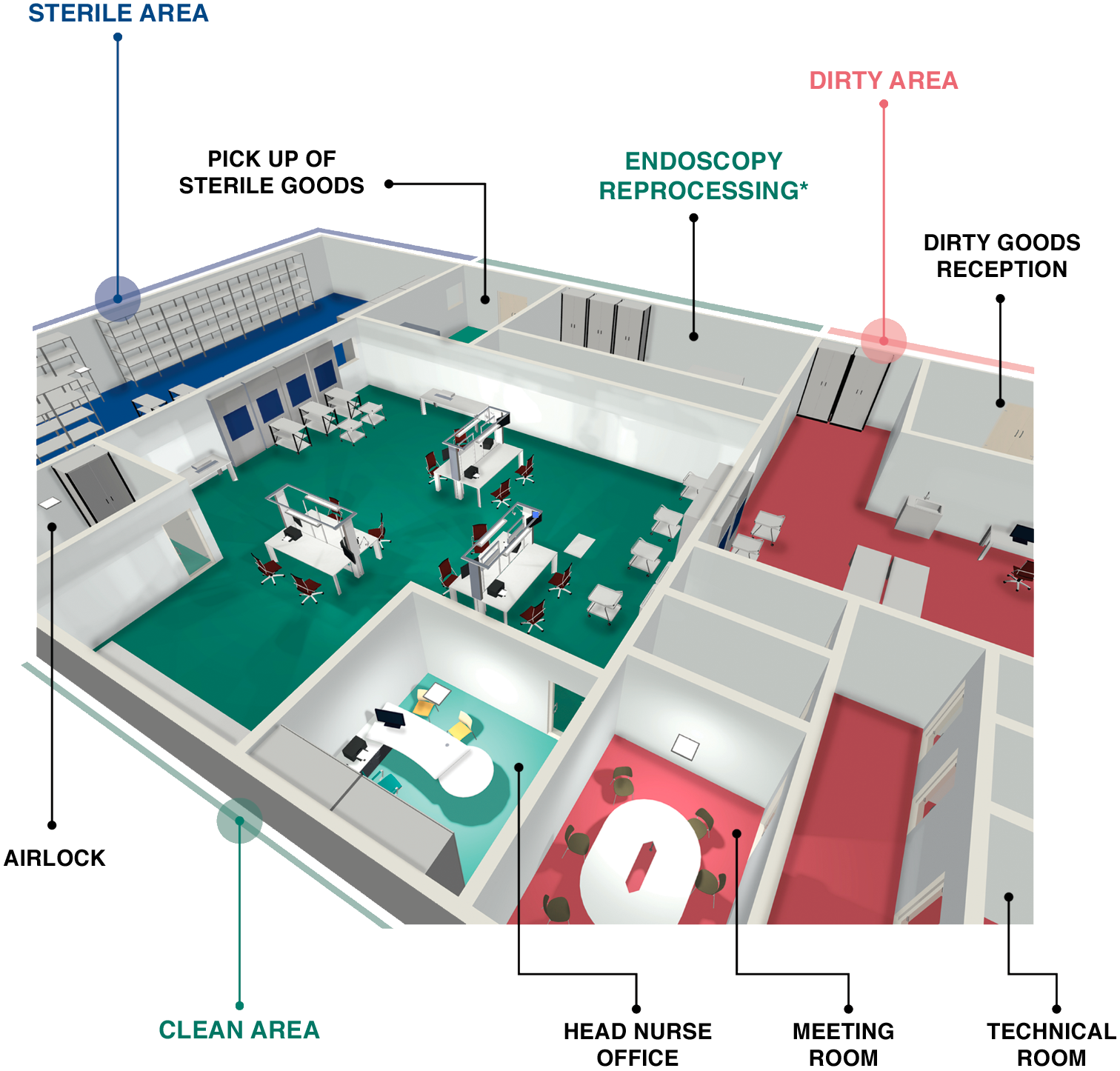

Central Sterile Services Department (CSSD)

■ DIRTY AREA

In the dirty area all the instruments and used devices arrive from the various departments and operating theaters that need to be reprocessed to be used again. In this first phase the transition to the clean area occur thanks to a disinfection process. In addition, a manual pre-wash and an ultrasound treatment could be needed.

■ CLEAN AREA

After the washing phase and automatic disinfection the goods are safe to be handled, although not sterile. In the clean area the instruments that come out from the disinfectors are packed, to be prepared to the following process in the sterilizer.

■ ENDOSCOPY REPROCESSING

lnside some centers this area is separateci from the esso. lnside this area there are machines that guarantee the high disinfection, or, as in the case of Mediqua, the sterilization of the endoscopes.

■ STERILE AREA

Following the sterilization process, the instruments are now available to be delivered right away in the piace of use or they are stored waiting to be used.

Main Features

Designed for a better experience

The steam sterilizers I CAN STEAM are designed for a simple and effective experience for the operators, thanks to the touch screen user friendly interface.

Supplied with steam

The sterilizers can be supplied with steam produced by an integrateci electrical steam generator, or by clean steam provided by the client (direct steam), or by an integrateci steam generator warmed through heat exchange with dirty steam of the facility (indirect steam).

Safety first

The machine is equipped with several safety devices, that makes it extremely reliable. These operate for example stopping the door closing when there are obstacles on the way; preventing the simultaneous opening of the doors (in the double doors model), to avoid cross-contamination; allowing the opening of the door only at atmospheric pressure. Everything always in compliance with current regulations. There are redundant temperature sensors, which refer to two separate control boards, to always ensure the efficiency of the sterilizer.

Tracking Data

The information of each cycle is recorded and printed. lt is possible to enter a tracking system of the operators with a barcode (and machine persona! password for each operator). Our system is compatible with the main tracking systems on the market.

Automatic

Automatic start: chance to program an automatic start with heating cycle and test cycles before the arrivai of the operators.

Energy Saving

An energy saving system is available on the generator (specifically for water and electricity), so that the sterilizer goes into stand-by mode and then there is either a complete cooling of the machine mode, or only a percentage reduction in consumption mode, so that in this second case the machine will be able to run again a cycle in a short time.

Front Panel

The control panel is covered with composite materiai carbon fiber panel, for a pleasant and unique effect.

Analogical reading system of the pressure inside the chamber through pressure gauges.

15″ capacitive multitouch screen in 4:3, that responds perfectly even to a touch with a glove, with a resolution of 1024 x 768 pixels and , a viewing angle of 178°, which allows the operator a perfect reading of the screen in any position, without loss of contrast and color. In the double door sterilizers, there is a 5″ capacitive multitouch screen on the unloading side, with a resolution of 800 x 480 pixels.

Automatic vertical / horizontal door, pneumatic / electrically operateci.

The door and all external surfaces are covered with insulating materiai to ensure an external temperature below 45°C, and preserve the operator.

Almost unlimited storage of cycles (100,000+), with the chance to export data through a USB key, which can be inserted in the front pane I.

Emergency button: red mushroom-) shaped button with light and acoustic signal, which can stop immediately the machine, so that the machine will automatically reach the safety condition.

External surface refined with a “Scotch Brite” satin finish, for perfect cleaning.

PC Windows 10 that allows strong customization for the customer and remote assistance. Reliable hardware that supports optimal working even in high temperature conditions.

Sterilization chamber made of AISI 316L stainless steel (AISI 316Ti on request). The bottom of the chamber is made in a way that allow perfect drainage of condensation. lt complies with the European directive PED 2014/68 I EU and with CE marking. The internal surfaces of the chamber and of the doors are subjected to electro-polishing treatment to obtain a smooth and compact surface, with high resistance to corrosive attack.

Steam jacket realized from a sheet of austenitic stainless steel AISI 316L. lts structure guarantees strength to the chamber and high heat exchange surface. The welding is carried out by a fully automatic robotic system that makes constant contrai of the results.

AII sterilizers can be supplied with internal loading trolleys, grids and external trolleys for handling which can be of fixed or variable height; automatic loading and unloading systems of the trolleys are available on request.

Main structural features

For the production of steam, you can choose between an electric steam generator, which works with electric heating elements, or a steam generator with heat exchanqer, in which the production of steam takes piace through heat exchange with the steam supplied by the customer, if the house steam is not suitable for direct use of the sterilizer.

Panels and frame made of AISI 304 stainless steel (AISI 316L on request).

Liquid ring vacuum pump that guarantees efficiency and performance, with high and stable vacuum levels (but as optional we can supply the device with an innovative dry vacuum pump, a system that allows to reduce the consumption of water of the autoclave because the pump is oil operateci).

Sterilization cycle control system via controller (PC) and master / slave system consisting of two electronic contrai boards with microprocessor developed by Mediqua, each managing an , independent system of pressure and temperature probes.

Main structural features

PC Windows 10 that allows strong customization for the customer and remote assistance. Reliable hardware that supports optimal working even in high temperature conditions.

Sterilization chamber made of AISI 316L stainless steel (AISI 316Ti on request). The bottom of the chamber is made in a way that allow perfect drainage of condensation. lt complies with the European directive PED 2014/68 I EU and with CE marking. The internal surfaces of the chamber and of the doors are subjected to electro-polishing treatment to obtain a smooth and compact surface, with high resistance to corrosive attack.

Steam jacket realized from a sheet of austenitic stainless steel AISI 316L. lts structure guarantees strength to the chamber and high heat exchange surface. The welding is carried out by a fully automatic robotic system that makes constant contrai of the results.

AII sterilizers can be supplied with internal loading trolleys, grids and external trolleys for handling which can be of fixed or variable height; automatic loading and unloading systems of the trolleys are available on request.

For the production of steam, you can choose between an electric steam generator, which works with electric heating elements, or a steam generator with heat exchanqer, in which the production of steam takes piace through heat exchange with the steam supplied by the customer, if the house steam is not suitable for direct use of the sterilizer.

Panels and frame made of AISI 304 stainless steel (AISI 316L on request).

Liquid ring vacuum pump that guarantees efficiency and performance, with high and stable vacuum levels (but as optional we can supply the device with an innovative dry vacuum pump, a system that allows to reduce the consumption of water of the autoclave because the pump is oil operateci).

Sterilization cycle control system via controller (PC) and master / slave system consisting of two electronic contrai boards with microprocessor developed by Mediqua, each managing an , independent system of pressure and temperature probes.

RELATED PRODUCT

iCanTrace

Management and reprocessing of the sterilization and use of surgical instruments